Well the weather man to be more accurate!

One thing that has always made me chuckle is the mystic art of weather forecasting. Despite huge super computers, satellites, weather stations and a whole host of other data sources mankind doesn’t seem to be able to get it right.

Take Michael Fish’s all time classic of October 1987!

I’m sure if they rolled a dice or span a wheel the forecast would come out the same!

Now it’s all well and good having a rebellious opinion but how about doing something about it? OK, let’s have a go and see what we can do.

As a kid I remember doing a school project where you had to collect weather data for a week and then produce little graphs and charts of your observations. My dad duly fashioned a weather vane out of some bits of wood and it balanced on an upturned nail to swing freely in the breeze, a rain collector fashioned out of a plastic Coke bottle buried in the ground, thermometer and mark one eyeballs to note the cloud formations. All good educational fun!

Fast forwarding 40 years and it seemed a good plan to update that principle of data collection and see what the modern environment can do with it. I like the whole concept of crowd data when it comes to meteorological matters (not so keen on other data harvesting especially when you don’t know it’s happening as the real posters ain’t this obvious believe me!)

I’ve been tempted on several occasions to buy and install an AccuWeather compatible weather station to throw my contribution into the mix. They’re not cheap which has been the main dissuader!

Added to that in Ham Radio land weather report exchanges regularly form part of contacts and an eye on all things meteorological goes very much with the territory.

So with all that in mind, while slumped in a deck chair between sinking fence posts into the ground I was pursuing the internet on my phone and stumbled across a very neat project on Instructables.com

To be honest I was drawn to the very neat little 3D printed enclosure that the designer had fashioned

more than anything else but the more I read the more intrigued I became and thought, why not?

Reading the article in full I realised I had 90% of the components already as my box of Arduino bits has a multitude of sensors and the like that have been bought and used in other test projects or just harvested at minimal cost for a rainy day project (I know, I know!)

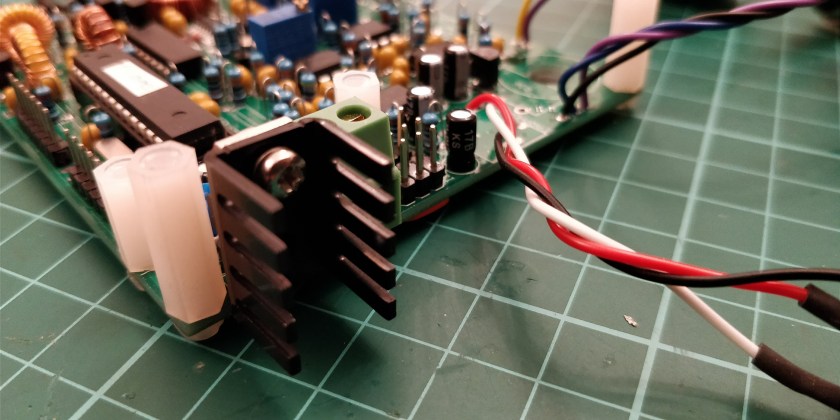

The evolution of the original project saw it grow into a PCB based build in version 2. Nothing against breadboard or strip board but I like a professional looking build. The added value of the PCB solution is the fact that if you use the include link in his post you get a voucher from PCBWay which negates the board cost in full, all you pay is postage and you get a very nice professionally manufactured board in return. In addition the author gets a kickback from the company which is nice as he has invested time and effort into this project and to tip him $10 for his contribution to the greater good of intellectual advancement and creativity isn’t a bad thing.

Not wishing to see him off but I’ve got a stack of the board’s left over as there’s a minimum quantity on the order. As such, as a first come first serve offer to my readers, if you’d like one, if you cover your postage costs I’ll send you one. Just drop me an email via the contacts page. When they’re gone, they’re gone.

I’m not going to do a whole blow by blow build shoot for this as time is tight but basically you take all of this, plus a few sensors and so on

And get this rather nifty, compact motherboard with all the daughter PCBs duly installed and ready to go.

This is an independent, self powering system which uses a solar panel to recharge a Li-Ion cell mounted on the board. Even on an overcast day enough UV is being harvested to maintain the battery which is quite impressive.

Now when it comes to the enclosure, despite the natty first iteration, it’s lacking on the weatherproofing front plus the external influences on the sensors due to its limited shielding means the harvested data won’t be as true as it could be.

Enter case version 2.0!

A full blown Stevenson Screen and printed with the trusty Prusa i3 MK3S. It took almost a week to print due to the complexity, well I say that, the multiple rings which are needed to build the vented housing. I really like it and it is both substantial and durable.

The project is another Internet of Things (IoT) concept and the data is being passed back to my home network over Wi-Fi where it disappears into the ether to be served up via Blynk or ThingSpeak. What you have is a home made data logger which is a bit of fun and can give you a what’s happening now snapshot in the weather department at your location.

How about stepping it up a bit and becoming a meteorological soothsayer? The code from this GitHub repository attempts this using the Zambretti Forecaster

So after running the weather station for several weeks what do I think?

There’s still a bit of fine tuning to be done. The battery needs it’s calibration factor adjusting within the sketch to give a true voltage and I need to thoroughly weatherproof the PCB with a conformal coating before I trust this little box of tricks to a permanent place in the garden, but overall I’m really please with this project.

Homebrew 1 – 0 The Met Office!